State-of-the-art corporate headquarters

This LEED Gold headquarters build-out features two towers and high-end amenities throughout.

Key Partners

- CBRE

- Cousins Properties

- HOK

- JLL

Awards & Certifications

- IIDA Georgia, Best Workplace—over 75,000 sf, 2022

- LEED Gold

Confidential

CONTRACT VALUE

10 months

SCHEDULE

775,000

SQUARE FEET

2021

YEAR COMPLETED

35.64

ACRES OF PARTITION DRYWALL THROUGHOUT CAMPUS

Norfolk Southern’s new headquarters is centered around innovation, sustainability, and employee wellness.

Client Goals

Norfolk Southern relocated their corporate headquarters from Norfolk, Virginia to Atlanta, Georgia where their operations and technology center was located. This move allows the company to be more agile and collaborative.

Design Vision

The design provides a space where Norfolk Southern team members could thrive. With activity-based work environments and nods to the company’s iconic brand throughout, the space emulates Norfolk Southern’s desire to foster collaboration and well-being.

Construction Focus

With more than 600,000 total working hours dedicated to this project, communication and team synergy were paramount. This project challenged us as builders to think outside the box and remain flexible to create innovative solutions as we experienced challenges.

Monumental Staircase

The monumental staircase spans three levels and features a 25-foot ribbon structure. More than 1,000 working hours were dedicated to install this ornamental staircase safely.

Full-Service Kitchen

The 6,000-sf full-service kitchen showcases five walk-in coolers, a pizza oven, multiple grills, and more than 500 additional pieces of equipment to service the restaurant-style food hall.

Network Operations Center

The 27,000-sf Network Operations Center houses 500 employees. This 24/7 center features 24-foot ceilings and large video screens to display the condition of every active train on the network. Within this space, engineers efficiently and safely manage routes and seamlessly communicate with train crews throughout the network.

At peak activity, there were more than 800 individuals on-site at any given time. While the scope of work was divided into three distinct teams—amenities, towers, and critical infrastructure—every project stakeholder worked closely to deliver this iconic project. HITT invested more than 600,000 working hours to deliver the final product.

“HITT was a tremendous partner in bringing our vision to life. They coordinated exceptionally well with all of our partners, helping to ensure the project was delivered on schedule, despite a pandemic. From the early stages, the HITT team was engaged, creative, and flexible, keeping us up-to-date on progress as well as challenges along the way. It was a pleasure to work with such dedicated and talented professionals.”

ANN ADAMS

Executive Vice President, Norfolk Southern

Unique Challenges, Smart Solutions

Ambitious projects require carefully constructed solutions

Challenge #1

With core and shell construction occurring concurrently, the interior build-out schedule followed progress of the base building. Due to an unforeseen deep foundation issue, both building teams learned that the building was sinking.

Solution

We reconfigured the overall project schedule to consider the foundation remediation. This challenged the project team to resequence the overall workflow of the project, while maintaining optimal workforce in each area.

Challenge #2

With mobilization beginning in early 2021, COVID-19 health and safety concerns were high, requiring thorough and thoughtful planning to keep the project on track and the workforce safe.

Solution

To manage health risks, we closely coordinated extensive COVID-19 protocols, such as having a check-in station at a single point of entry to the jobsite. This process resulted in zero time lost on the project, allowing the project to stay on-schedule.

Challenge #3

With a workforce of more than 800 people on-site at any given time, safely installing the large, monumental staircase was a challenge.

Solution

We worked closely with the core and shell contractor to identify points of contact to calculate exact deflection measures during construction of the steel structure within the base building. These extensive measures resulted in a safe installation.

High-end Amenities

Designed for the employee experience, this headquarters features high-end, light-filled spaces.

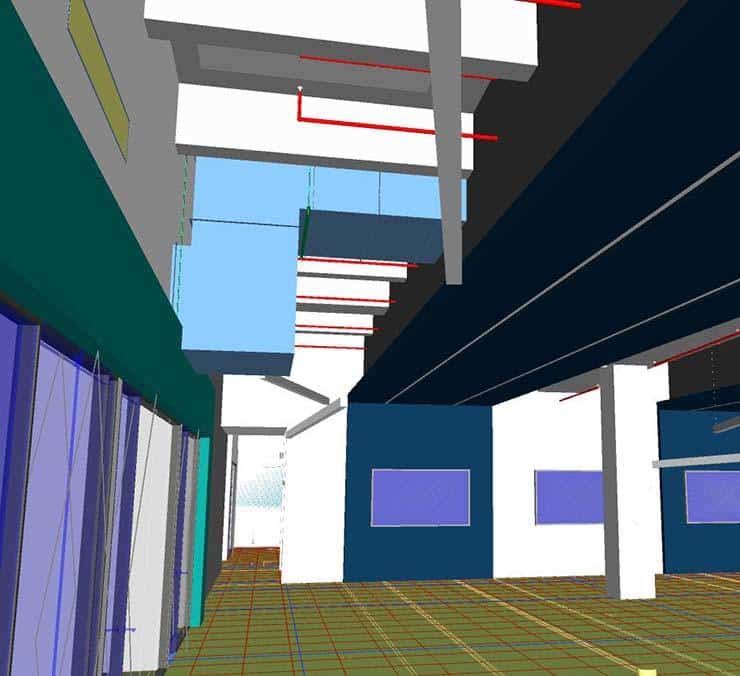

Virtual Construction

By using building information modeling (BIM) early in preconstruction, HITT detected and mitigated 1,800 clashes, resulting in cost savings of approximately $1.7 million.

Quality Control

The HITT team created a floor mock-up to model how certain finishes would be integrated. We also used a mock-up log to document more than 100 details and approvals, ultimately reducing the number of punchlist items.

Every Little Detail

The space features unique programming that acts as a catalyst for innovation and collaboration.

Key Team Members

News & Insights

Let's chat.

Work With HITT

Learn More