State-of-the-art operating room suite prototype for Inova Health System

HITT modernized the existing ground floor surgery center for the Washington, DC region’s leading not-for-profit healthcare system. The renovated 30-room operating suite supports Inova’s mission of providing world-class healthcare to the community.

Key Partners

- Inova Design & Construction

- Leach Wallace (WSP)

- Wilmot Sanz

Awards & Certifications

- LEED Certified

- American Society of Health Care Engineering (ASHE), Vista Awards, Renovation, 2024

Confidential

CONTRACT VALUE

48 months

SCHEDULE

40,000

SQUARE FEET

2022

YEAR COMPLETED

400+

MEDICAL GAS WALL AND BOOM OUTLETS

The modernization of the OR suite at the Fairfax Medical Campus provided Inova Health System with a forward-looking opportunity to standardize the OR suite design as a prototype that could be implemented in other Inova hospitals in the future.

Client Goals

To support Inova’s mission of providing world-class healthcare to the community, the new OR suite retains and attracts top surgeons and doctors to work in this premier medical environment, while providing the variety of advanced surgical procedures and ORs necessary to support patients in the region.

Design Vision

The goal was to deliver an efficient, leading-edge OR suite prototype to better support doctors, nurses, and day-to-day OR operations. The surgery department expanded over the course of several decades, resulting in a disjointed clinical flow and outdated design standards. The in-place renovation aimed to deliver a cohesive, modern surgical platform, with all 30 operating rooms sharing workflows, new technology, and best practices in operating room design.

Construction Focus

The large, complex renovation occurred in an occupied and operating healthcare environment. To allow hospital operations to continue running with minimal disruption and life-saving procedures to still be performed, the implementation included five construction phases—including 16 subphases—to allow the live operating rooms adjacent to each phase’s construction boundary to remain inactive.

Epoxy Flooring Selected for Ergonomics and Maintenance

High-performance epoxy-based Stonhard flooring required a 10-day installation process. Creating minimal seams and requiring no adhesive, this type of floor is utilized for sterile environments for easier cleaning and maintenance. Additionally, this flooring provides better ergonomics for doctors, nurses, and medical staff who are on their feet for surgical procedures.

Advanced Ceiling Systems

Integrated Laminar Ceiling System helps to guide particulate away from the surgical site to mitigate the risk of airborne particles for the protection of both the patient and the staff.

OR Suite Footprint Spans Three Buildings, Creating Complex Infrastructure Coordination

To ensure continued operation of the facility, extensive communication between HITT, Inova, subcontractors, the county, design team, and commissioning agent was critical in achieving continuity and schedule. HITT created plans to maintain utilities to active area including temporary services until the existing infrastructure could be demolished and the new systems built and commissioned.

To provide an exceptional experience, HITT built seven unique mock-ups of the various ORs for the surgeons/doctors to accommodate specific user requests—such as where the medical gas is located within the room, varying power requirements, locations of large/heavy pieces of equipment, different rough-ins for equipment, and storage requirements. The attention to detail in these mock-ups ensured that each room was built to the specifications of the doctors/surgeons who will be operating in each room. With safety first in mind, Inova selected HITT and placed much trust in the team to build this complex three-year, multi-phase, in-place renovation in an occupied healthcare environment.

“HITT’s field staff established a strong rapport with the clinical team at the project’s onset. They closely communicated noise and operational impacts and were always responsive to staff concerns. HITT displayed a strong partnership with their subcontractors to develop detailed phasing plans and coordinate infrastructure replacements to ensure the continued operation of adjacent operating rooms. They overcame a multitude of project challenges and unforeseen issues through strong collaboration with the project team and a positive, assertive approach to problem resolution. There’s no other team that I would trust more for such a critical and complex project.”

RYAN BRADLEY

Project Manager, Design & Construction, Inova Fairfax Medical Campus

Unique Challenges, Smart Solutions

Sometimes, ambitious projects may need carefully constructed solutions.

Challenge #1

Construction occurred in an active hospital and required close coordination with Inova to minimize impacts to the active surgery department and operating rooms.

Solution

Surrounding each phase of construction, temporary double-sided soundproof drywall walls were installed from deck to deck, sealed, and inspected prior to the demolition of each phase. The construction space was negatively pressurized to ensure no dust was pushed out of the space and into the hospital areas. This work occurred during weekends or nights, due to partial corridor closures which affected hospital workflow. All noisy work occurred off-hours to prevent interruptions to active operations and accommodate doctors, patients, nurses, and support staff.

Challenge #2

Surrounding spaces were fully sterile, active operating room suite areas. Any personnel outside of the construction space was required to wear a full cleanroom suit or scrubs.

Solution

The site logistics were developed to allow construction access through the exterior of the building, which minimized foot traffic through the hospital by creating an exterior masonry opening for each phase of construction. For any work above the ceiling or creating dust, outside of the phased construction space, all personnel were required to wear clean room suits. All work occurred out of a plastic bubble or a negatively pressurized infection prevention containment with an ante-room.

Challenge #3

A five-phase schedule/site plan morphed into a 16-subphase plan. As the first original phase was underway, the client and hospital staff had concerns regarding corridor closures and daily hospital traffic.

Solution

HITT reevaluated each phase into 2–4 subphases to allow for corridor sharing for access to and from the Emergency department, pre- and post-op, control room, pharmacy, and active ORs were satisfactory to hospital leader requests. The total phase breakdown includes 16 subphases with each of the major five phases requiring full infection control/prevention barriers at the highest standard to ensure no disruptions to the surrounding operating rooms. Every construction containment that was set up was approved by the hospital’s infection prevention as well as life safety and egress teams.

The Process

Development of an Operating Room

The 30 operating rooms include: three neurology, one negatively pressurized/isolation neurology, four orthopedic, one perfusion cardiovascular, one hybrid, five robotics, four transplant, two cystoscopy, and eight standard or multi-use operating rooms. Seen here is the progression of a typical operating room.

Sustainability

Energy performance was optimized through design, creating a twelve percent reduction in energy usage from baseline. In addition to energy savings, attention was placed on sustainable materials from an environmental disclosure and a health and wellness perspective. The project is on track to achieve materials disclosure and low-emitting materials credits. HITT worked with a third-party verified recycling facility to recycle more than 80 percent of all demolition and construction waste, totaling over 400 tons. These sustainable attributes, air testing, and quality control processes allowed the project to achieve LEED v4 certification.

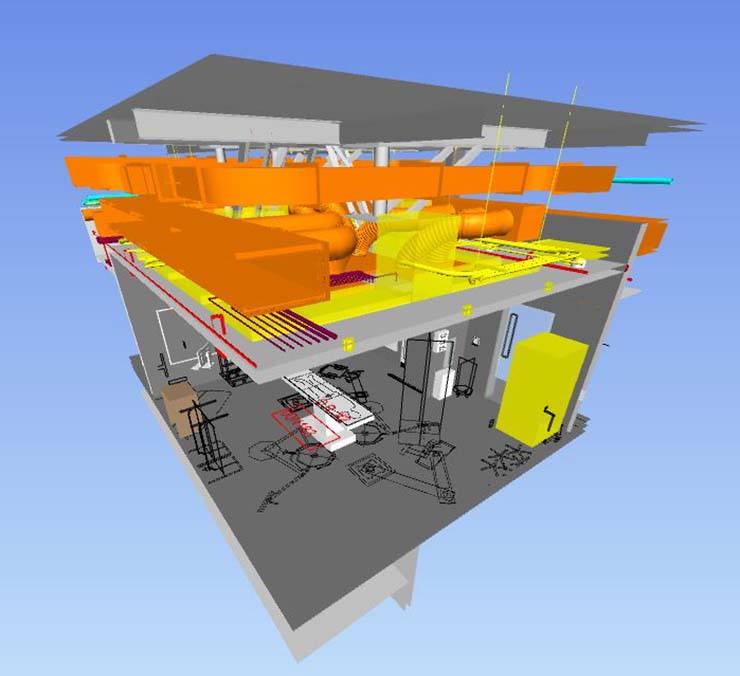

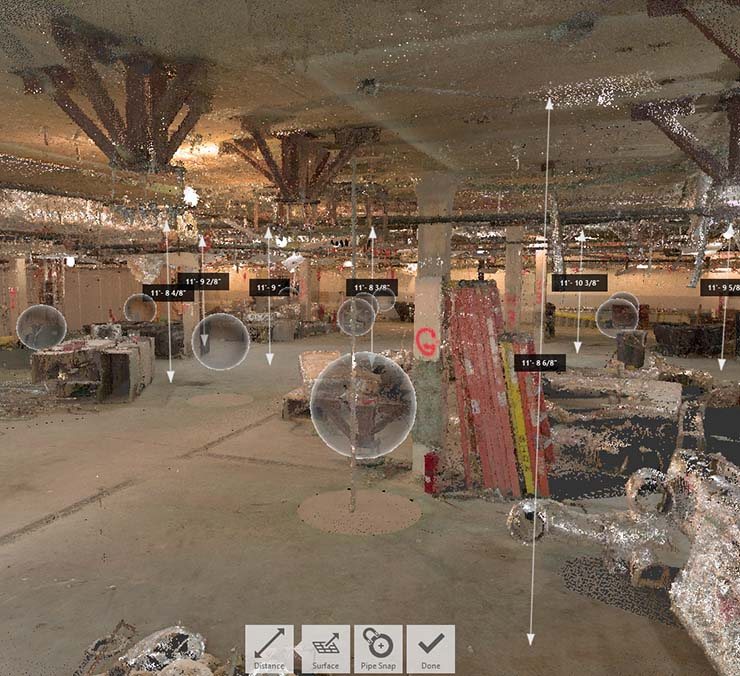

Virtual Construction

The project relied on extensive Building Information Modeling (BIM) coordination alongside the design team and subcontractors. This collaborative effort expedited design changes, resolved coordination items months in advance of construction, and prevented any rework.

Laser scanning was used after the demolition of each major phase. The resulting point cloud was utilized for floor leveling to verify existing dimensions and incorporate them into the BIM coordination model. This view of the existing dimensions helped inform mechanical design changes to work within the existing space.

The Results

Modernization and Reconfiguration

The reconfiguration provides larger operation rooms, improves overall circulation and workflow efficiency including a continuous sterile core, and adds new hybrid operating room to support highly complex, advanced surgical procedures at the flagship Inova facility.

Key Team Members

News & Insights

Let's chat.

Work With HITT

Learn More