Occupied cGMP cleanroom expansion

Located inside a two-story occupied building, this active cleanroom expansion features a new utility yard.

Location

Durham, North Carolina

Key Partners

- Hanbury Evans Wright Vlattas + Company

- Development & Construction Insights

- Newcomb & Boyd

Client

University of North Carolina (UNC) Health

Project Type

$5,200,000

VALUE

35 weeks

SCHEDULE

12,300

SQUARE FEET

2021

YEAR COMPLETED

23,000

LBS OF DUCTWORK

As part of the UNC Lineberger Comprehensive Cancer Center, this space provides UNC staff with an ISO 7 environment to support cellular therapy clinical trials.

Client Goals

Established in 2015, the Advanced Cellular Therapeutics Facility supports the UNC Lineberger Comprehensive Cancer Center. This lab is used by a core staff of experts to generate and expand cellular therapy products for custom cancer treatments under current Good Manufacturing/Tissue Practices (cGMP/cGTP).

Design Vision

The new and improved design within the irregular existing footprint allows for a more efficiently functioning lab and support spaces.

Construction Focus

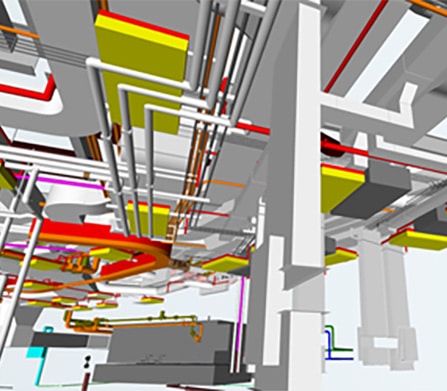

The challenging logistics of this project required meticulous attention to detail to overcome the limited overhead clearance height. Small deviations have big impacts and our team used building information modeling (BIM) to model all overhead rough-ins to ensure every detail was considered.

Exterior Equipment Yard

The expansion required a new 40-ton air handler, 110-ton chiller, redundant boiler skid and pump packages, and quad exhaust fans capable of moving 27,000 cfm of exhaust air.

cGMP Practices

“Thinking clean” is a necessary mindset even during construction. HITT implemented a custom clean-build protocol to establish procedures for all stages of construction.

Phased Turnover

Early turnover of the administrative area was required to start renovations on existing, active lab areas.

HITT maintained great communication throughout the project with weekly meetings, thorough project updates and minutes, and continuous communication with the UNC project management team. We had a unique situation with a third-party building tenant requesting weekly meetings with HITT, UNC, and the landlord to receive updates on construction for transparency and communication. HITT was more than willing to meet this request, complete the third party’s project forms, and comply with any other requests that were made. This flexibility and support made it easier for UNC.”

Heather Grant Morefield

Executive Director—Real Estate, UNC Health

Unique Challenges, Smart Solutions

Ambitious projects require carefully constructed solutions

Challenge

Supply chain delays affected nearly all laboratory equipment in the facility, posing a threat to the overall schedule as long lead times would impact the sequencing of work.

Solution

To successfully manage the supply chain impacts, our team focused on clear communication. We aggressively managed the supply chain while tracking long lead items.

Challenge

Pfizer’s active cleanroom facility on the floor directly above the project required additional considerations for site logistics and sequencing.

Solution

Our team coordinated weekly calls with Pfizer to share schedule updates and review tasks that could potentially impact their operations. When power needed to be shut down, we provided three-week notices and backup generators to minimize disruption to their operations.

Challenge

The installation of overhead MEP systems was challenging due to the limited plenum space of 30-inches above hard-lid ceilings.

Solution

We utilized an as-build laser scan and developed a coordinated model to pre-fabricate long runs of piping and duct work. Alternate duct shapes and equipment selections were made where the specified equipment did not fit.

Virtual Construction

The project team used extensive BIM coordination during preconstruction to ensure ease of maintenance of overhead infrastructure once construction was complete.

The Results

Key Team Members

News & Insights

Let's chat.

Work With HITT

Learn More